Carter Plastics:

Delivering Precision and Quality in Injection Molding

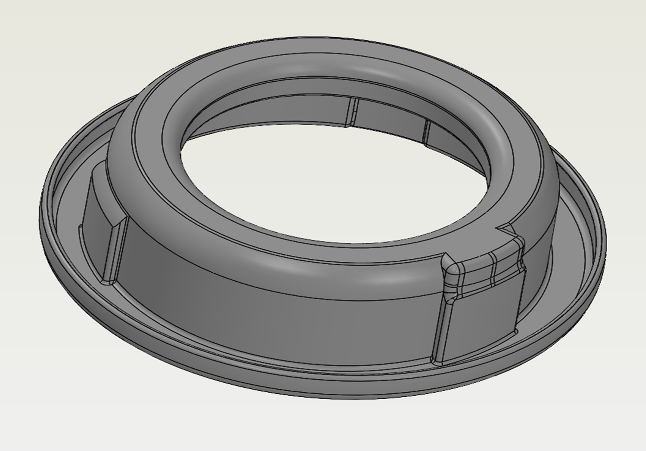

At Carter Plastics, we pride ourselves on exceeding customer expectations through state-of-the-art injection molding technology and expert craftsmanship. Our commitment to quality and innovation has made us a premier partner for high-quality plastic components across various industries. In this case study, we highlight a successful project involving the design and production of custom end caps. This project required a collaborative approach to meet specific customer requirements, including design elements from existing samples, friction fit capabilities, and multiple color specifications, while ensuring the production of 120,000 parts annually.

Customer Requirements

The client approached us with a need for new end caps that combined elements from two provided samples. The requirements included:

- A new design incorporating features from both samples

- A friction fit with the provided tube to ensure secure attachment

- Minimal flash to protect the product when being removed

from the tube - Capability to produce multiple colors to meet aesthetic needs

- An annual production volume of 120,000 parts

Design Process

Our design process emphasized collaboration and precision to meet the client’s expectations:

- Collaborative Custom Design: We worked closely with the client to develop a custom design that incorporated the desired features from both samples.

- Customer Approval: The design was reviewed and approved by the client, ensuring it met all specified requirements.

- Material Selection: We selected PA 6/6 material for its durability, aligning with the customer’s performance expectations.

- Color Customization: Our unique post-molding dye process allowed us to achieve the required multiple colors.

Mold Design and Build

To efficiently produce the end caps, we designed and built a mold tailored to the client’s needs:

- 4-Cavity Mold Base: The mold was designed with four cavities to meet the customer’s annual demand and part specifications.

- 110-Ton Press: We used a 110-ton press to ensure efficient and consistent molding.

- Trial Run and Approval: A trial run was conducted to produce sample parts, which were then approved by the client, confirming the quality and functionality of the end caps.

Value Added Service

To further enhance the project, we offered additional services that added significant value:

- Custom De-Gating Machine: We developed a custom de-gating machine designed to ensure no sharp edges on the gate, improving the safety and quality of the end caps.

- Any Color Option Available: Our process allowed for any color option, giving the customer flexibility to meet specific branding or aesthetic requirements.

By leveraging our expertise in injection molding and our commitment to customer satisfaction, Carter Plastics successfully delivered a high-quality solution that met the client’s precise requirements. This project exemplifies our dedication to providing professional and economical turnkey approaches for our customers’ plastic injection molding needs. We look forward to continuing to serve our clients with innovative solutions tailored to their specific demands.

Made in the USA